100L Micro High Flow Rate Cartridge Filter Housing Beer Brewing Equipment

Main Features

Inner-Jacket(SUS304)thickness: 3.0mm

External-Jacket thickness: 2.0mm

Seal head thickness: 3.0mm

* High quality insulation effect

Polyurethane thickness: 80mm

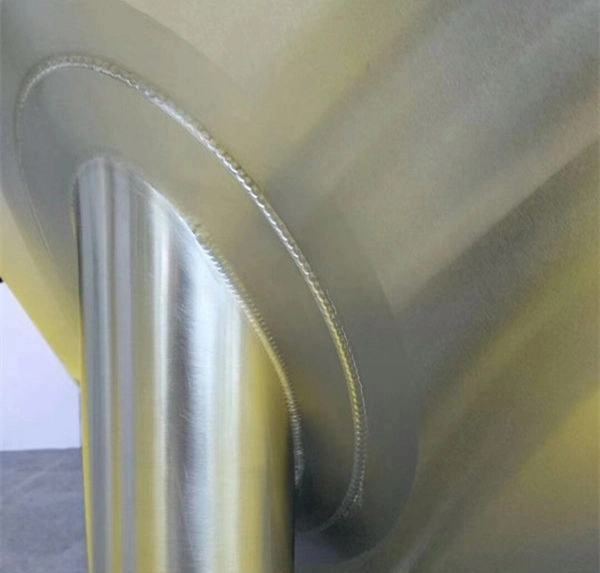

* Beautiful weld and polish technology

All argon gas protection welding. Polishing precision up to Ra0.6µm.

* Powerful technology supporting

Providing drawing of every tank and drawing the layout of the whole project according with

customer's workshop

* World's top brands' electronic components

For example, we use Siemens PLC and touch screen, Schneider button of circuit breaker, Airtac electromagnetic valves and other pneumatic parts, etc.

* CE certificate and UL certificate

All our products can pass CE certificate. If you need, we can also apply the UL certificate for you.

* Good aftersales service

Providing abroad installation and training and providing 1 year spare parts in free of charges

Technical Parameter

| Mashing system | capacity | 100L | 200L | 300L | 400L | 500L | 1000L | 2000L | 5000L |

| Output/batch | 100L | 200L | 300L | 400L | 500L | 1000L | 2000L | 5000L | |

| Brew/week | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 | |

| Output/week | 600~ 1000L | 1200~ 2000L | 1800~ 3000L | 2400~ 4000L | 3000L~ 5000L | 6000~ 10000L | 12000~ 20000L | 30000~ 50000L | |

| 6pcs fermentation tank | Output/batch | 600L | 1200L | 1800L | 2400L | 3000L | 6000L | 12000L | 30000L |

| Fermentation time | 6-8 days | 6-8 days | 6-8 days | 6-8 days | 6-8 days | 6-8 days | 6-8 days | 6-8 days | |

| Output/month | 1800-2400L | 3600- 4800L | 5400-7200L | 7200-9600L | 9000-12000L | 18000-24000L | 36000-48000L | 90000-120000L |

| This brewhouse is for a 1000L which can be used at brewery. It has three vessels(Mash tun, lauter tun and kettle/whirlpool tank with a hot water tank. If you need, we also can provide you with the 2 and 4 vessels brewhouse and a hot water tank. |

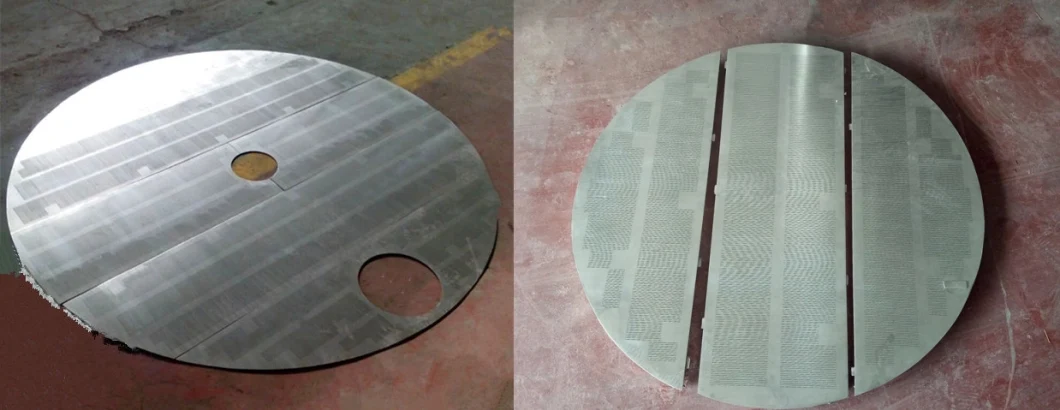

| As you can see in the above pictures, we can provide many kinds of rakers in the luter tun, the raker can moved up and down as your needs automaticly or manually. The spent grain outlet also can be automatic or manulay. It's up to you!! |

| Plate-type Heat Ex-changer with double-section cooling: (water-cooled + glycol cold). |

| The perfect polishing. our inner polishing accuracy can be Ra0.2-0.4µm. |

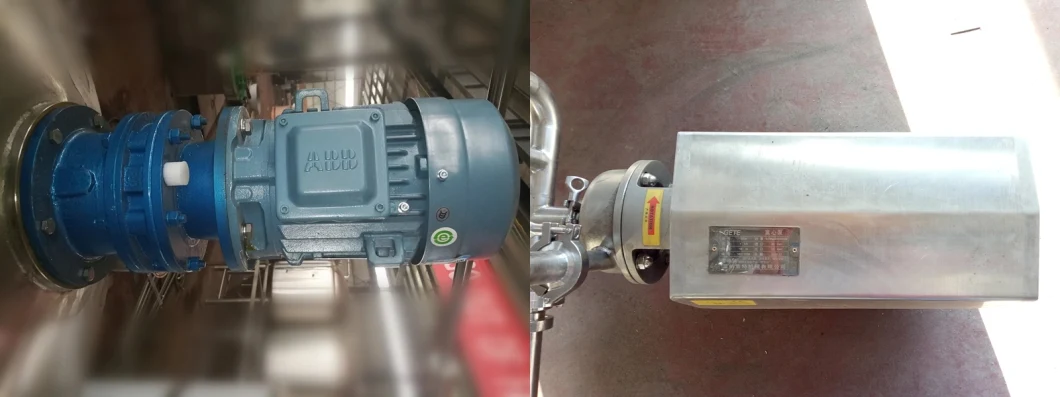

| We use ABB motors and VFD Food grade efficient centrifugal pump. |

| The sieve is milled one in lauter tun. The filter plate gap is less than 0.7mm and the load of sieve is about 250kg/m2. It is made by machine. The gap is more well-distributed. Never leak spent grain. In addition, it's easy to take the milled sieve out of the lauter tun because it has three parts. |

| The perfect welding. |

Our Factory

HIMAX company is located in Hi-tech Development Zone, Jinan, Shandong province, near Jinan international airport and Qingdao port, so it is convenient for land and sea transport. There are 80 employees, including 20 engineers and after sales engineers, the strongest after sales team in China, who are professional in mechanic, craft, and electric control.

With the purpose of customer's satisfaction and the management of "convergence of wisdom, quality assurance", HIMAX company offers more high quality products and excellent service, and helps the customer to establish more value.

| Outside Pachage | Wooden Packing as Exportand Standard. |

| Delivery time | 20-25days after received 40% of the whole payment. |

| Shipping forwarding | We can be resonsible for the shipping ,of course,we can also accept and cooperate with your agent if you have shipping forwarder in China |